Sika floor -264 20KG Kit Including Pigment Paste – Sika EPOXY Suitable for floors up to 70sqm/a coat

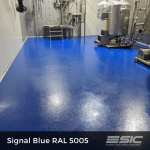

Sikafloor264 is a premium grade, 100% solids high build multi-purpose, self-smoothing roller applied epoxy floor coating resin designed to protect concrete floors and offer seamless durable floor protection.

Advantage of Sikafloor 264 Epoxy Resin

- Low VOC – 34 Grams per a litre

- Excellent chemical and mechanical resistance

- Easy Application

- Excellent hot tyre pick-up resistance

- Excellent wear and abrasion resistance.

- Excellent fuel and chemical resistance.

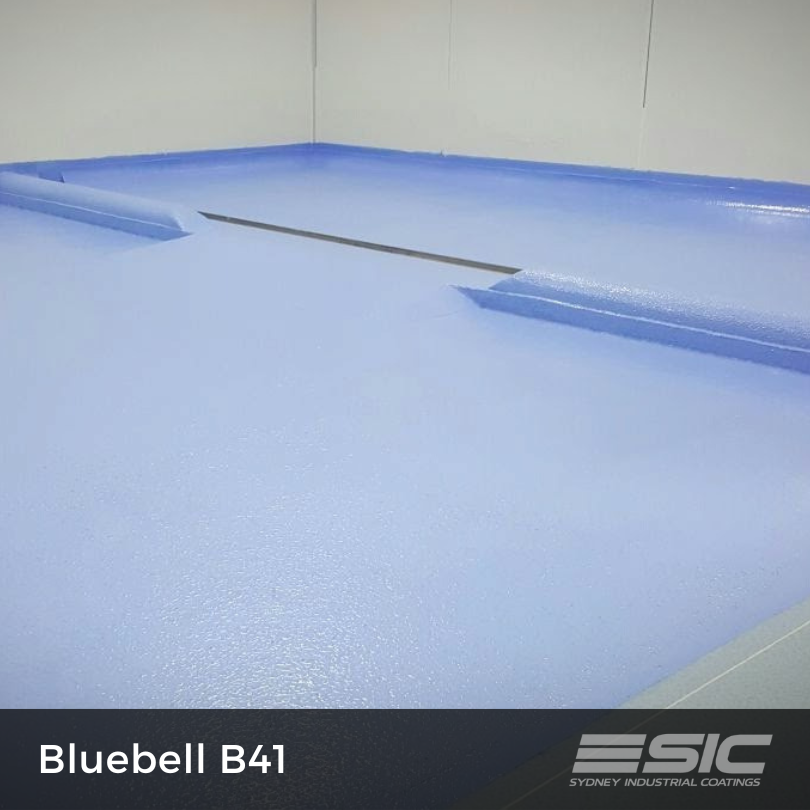

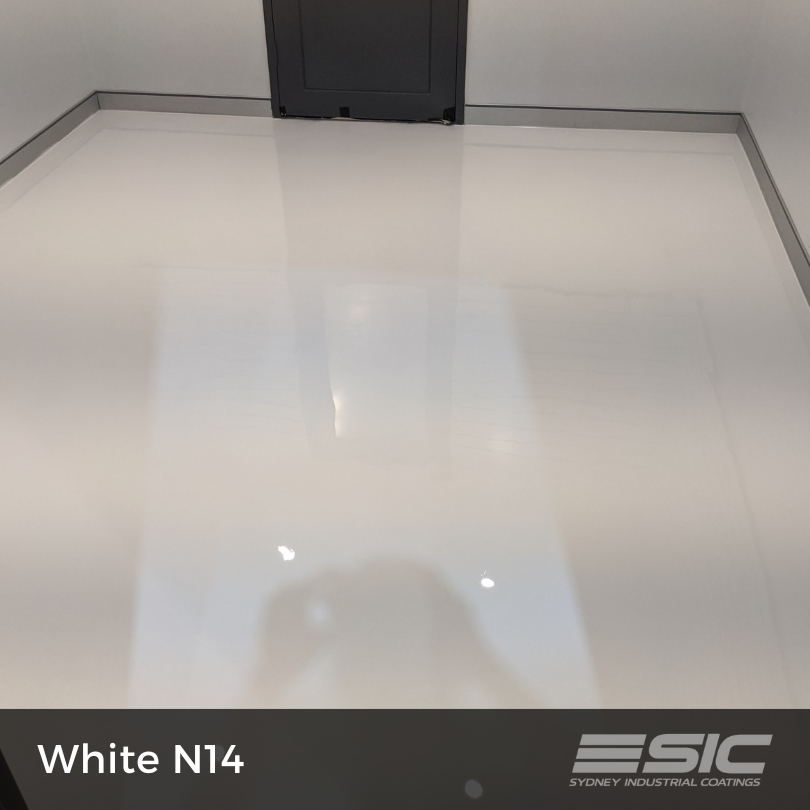

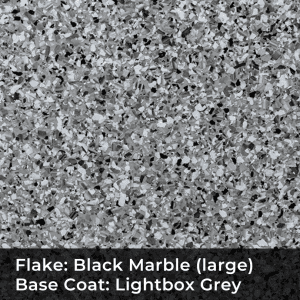

- Produces smooth and glossy finish, slip resistance floor finishes can be achieved by adding anti-slip media to the coating system.

- Easy application by brush, roller, squeegee, or spray equipment.

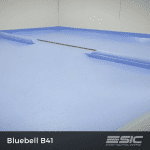

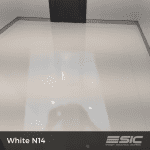

- Available in a wide range of colours to achieve an attractive & aesthetically pleasing finish.

Areas of use

- Garage floors

- Warehouses

- Manufacturing facilities

- Carpark decks

- Clean rooms

- Educational trade facilities

- Aircraft hangers

- Schools

- Mechanical workshops

- Commercial kitchens

Sikafloor 264 Epoxy Packaging /20Kg Kit Size

Sika floor 264 20Kg Kit Contains:

Part A: 13.09 kg

Part B: 4.0 kg

Pigment: 2 x 1.15 kg of Epoxy Pigment

PART A+ PART B + Pigment = 19.39 Kg or 14.9 Litres

For smaller projects, you might consider purchasing Sikafloor 264 in 10 kg kits.

Recommended Preparation Method

Preparation is the key to achieving a long-lasting floor-coating system

Diamond grinding is recommended method of preparing new & old substrates prior to applying Sikafloor 264 20 kg Kit

The purpose behind concrete grinding is to remove any flaking paint and other types of contamination to achieve a clean surface as well as remove any sealer or curing agent and open concrete pores allowing 1st coat of Sikafloor 264 to penetrate deep into the surface and seal the floor.

Acid Etching might be used as an alternative option to prepare the floor for more information on how to acid etch your floor click here to be directed to an external blog. Hydrochloric acid can be purchased from pool shops or local hardware stores

Recommended diamond tooling grits to prepare the floor prior to applying Sikafloor 264 20kg Kit

- 30/40 grit for hard concrete

- 80 Grit on soft concrete

- PCD plugs to remove flaking paint and then use grinding shoes to smooth out the floor before applying the coating.

Consumption Coverage Guide| 20 kg pigmented SIKA EPOXY kit applied using a 11 – 12 mm nap roller

| Area Size | 1st coat | 2nd Coat | Recommended Minimum no of coats | Required no of kits |

| Up to 30m2 | 10 kg | 9 kg | Two coats | One Kit |

| 30 -60m2 | 19 kg | 19 kg | Two coats | Two Kits |

| 60-90m2 | 29 kg | 29 kg | Two coats | Three Kits |

Notes

- Please use the table above as a guide only, as the consumption could depend on the application method/style and porosity of the surface.

- Applying additional coats to the floors subject to heavy traffic is recommended

- Thin down the first coat by adding 5%- 7% of general-purpose thinners

- A slip-resistance surface covering can be achieved by adding anti-slip media

Guide to achieving R or P rated slip resistance floor covering using different grit anti-slip media

| Slip Rating | P3 or R10 | P4 or R11 | P5 or R12 |

| Recommended Product | Boral 30/60 sand

80 grit Aluminum Oxide |

Boral 1mm sand

46 or 30 grit Aluminum Oxide |

Boral 1mm sand

24 grit Aluminum Oxide |

Document Download, Sikafloor 264 Epoxy technical Data Sheet and Safety Data Sheets

Click on the tiles below to download Sikafloor®-264 Technical Data Sheets and Safety Data Sheets.

Sikafloor 264 – Sika’s Website

James Carroll –

Applied this product over Sika94 and the finish product is great

Joe Larson –

Very easy to apply. Excellent coverage.