PREMIUM GRADE, AUSTRALIAN MADE, SELF-LEVELLING 100% SOLIDS EPOXY FLOOR COATING KIT SUITABLE FOR WAREHOUSES, WORKSHOPS & SHOWROOM FLOORS

E4110 is a gloss, self priming floor coating epoxy product, Its available in 10 litre kit sizes and each kit will cover 50sqm*/a coat of floor space. A & I Coatings ENVIROSET 4110 is a two-pack pigmented, solvent free, 100% solids epoxy with excellent surface hardness and adhesion. It exhibits high water resistance, chemical and oil resistance with the ability to build virtually unlimited film thickness. Perfect for warehouse, workshops & showrooms epoxy flooring.

Advantages:

- Excellent for protecting old and new concrete surfaces

- Low VOC

- Excellent chemical and mechanical resistance

- Excellent hot tyre pick-up resistance

- Excellent wear and abrasion resistance.

- Excellent fuel and chemical resistance.

- Produces smooth and glossy finish, slip resistance floor finishes can be achieved by adding anti-slip media to the coating system.

- Easy application by brush, roller, squeegee, or spray equipment.

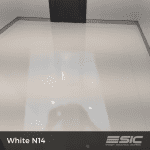

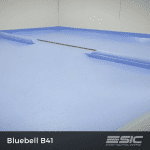

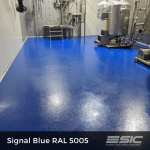

- Available in a wide range of colours to achieve an attractive & aesthetically pleasing finish.

Highlights of E4110

- 100% Solids, Australian made resin – LOW VOC

- 10 lit kit is economical and easy to mix and apply

- Premium low yellowing product, suitable for

- Warehouses | Economical, excellent wear resistance, low yellowing

- Air craft hangars and mechanical workshops | Oil & fuel resistance, excellent mechanical resistance

- Offices, Showrooms | Suitable for areas exposed to sun most times, high wear resistance

- Garages | Oil, fuel and hot tyre pick up resistance, High gloss and low yellowing

- Metallic Epoxy marble finishes | Self level, premium resin and will provide an excellent finish

EPOXY FLOORING E4110 MATERIAL AND SAFETY DOCUMENTS DOWNLOAD

Click on the tiles below to download A&I coatings E4110 Technical Data Sheet and Safety Data Sheets.

Visit A&I Coatings.

Contact Sydney Industrial Coatings for any inquiries.

RECOMMENDED PREPARATION METHOD PRIOR TO APPLYING REAL EPOXIES

Recommended diamond tooling grits to prepare the floor prior to applying A&amp;I Coatings E4110</em></strong>

Diamond grinding is recommended method of preparing new & old substrates prior to applying A&I Coatings E4110

The purpose behind concrete grinding is to remove any flaking paint and other types of contamination to achieve a clean surface as well as remove any sealer or curing agent and open concrete pores allowing 1st coat of A& I Coatings E4110 to penetrate deep into the surface and seal the floor.

Acid Etching might be used as an alternative option to prepare the floor for more information on how to acid etch your floor click here to be directed to an external blog. Hydrochloric acid can be purchased from Bunnings, pool shops and local hardware stores

Preparation is the key to achieving a long-lasting floor-coating system

Guide to How much product you will need to cover your space using A & I Coatings E4110

Consumption will depend on the following factors:

<ul>

ce

porosity | to acheive best results, old and soft concrete may require an additional coat of epoxy

- Application method | Squeege application method will use more product but will provide better finish, alos size of the roller nap and amount of product applied to the floor can play a big roller in consumption rate.

Consumption Coverage Guide | 10L pigmented E4110 Epoxy Flooring kit applied using a 11 – 12mm nap roller

| Area Size |

1st coat |

2nd Coat |

Recommended Minimum no of coats |

Required no of kits |

| Up to 50m2 |

idth=”99″>10 liters |

10 liters |

Two coats |

Two Kits |

| Up to 100m2 |

20 Liters |

20 Liters |

Two Coats |

Four Kits |

| Up to 150m2 |

30 Liters |

30 liters |

Two Coats |

Six Kits |

Anti-Slip Media for Epoxy flooring to meet Australian Safety Standards

The anti-slip media supplied with this pack will not pass slip rating testing, if your project requires a specific slip rating, use the chart below as a guide to achieve R or P rated slide resistance floor covering using alternative grit anti-slip media. Information below should only be used as a guide and applicator must ensure the end product meets the required slip rating.

| Slip Rating |

P3 or R10 |

P4 or R11 |

P5 or R12 |

| Recommended Product |

Boral 30/60 sand 80 grit Aluminum Oxide |

Boral 1mm sand 46 or 30 grit Aluminum Oxide |

Boral 1mm sand 24 grit Aluminum Oxide |

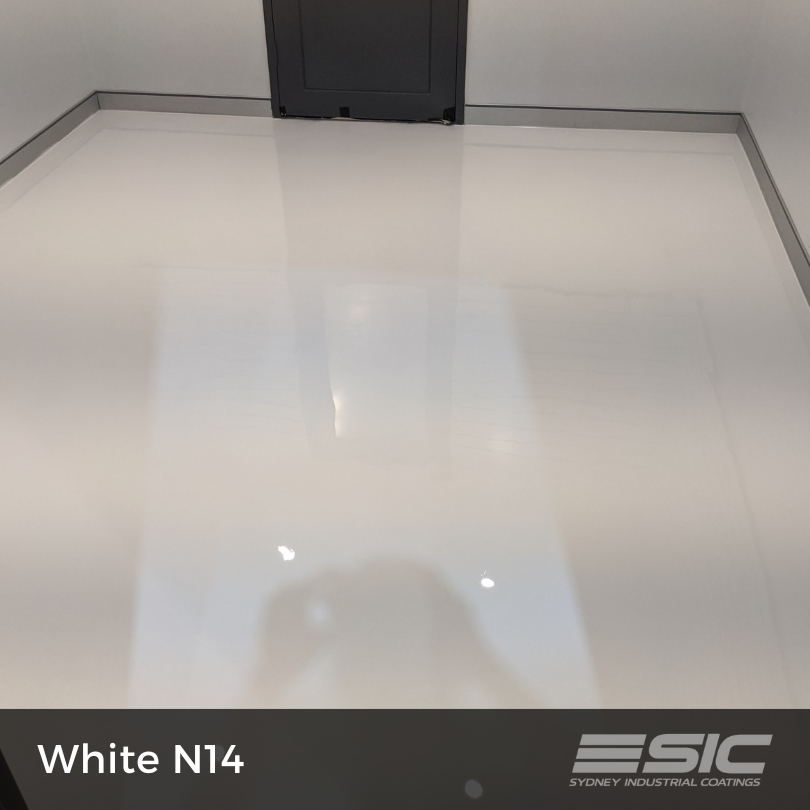

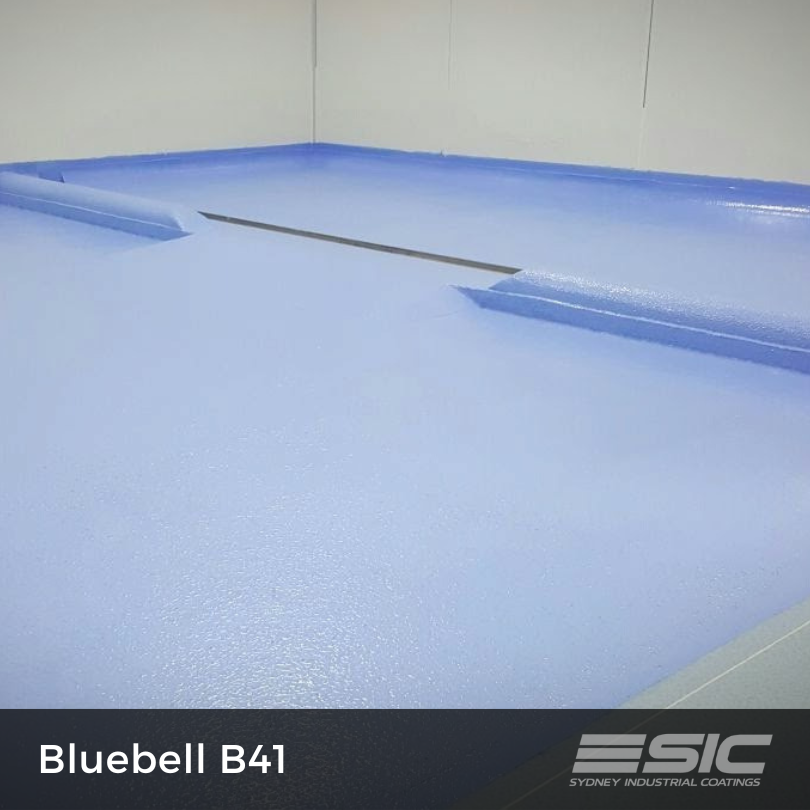

Colour accuracy disclaimer: We have taken care to display the most accurate visuals of our products. However, we are not responsible for the colour accuracy of the device you are viewing our swatches on. These variations arise due to different computer monitors and devices (make, model and technology, as well as resolution, contrast and brightness control settings) in much the same way a scan will differ from an original image and a colour photocopy. Furthermore, coatings can exhibit variation in perceived colour depending on gloss level and application method. If you require a very specific colour match, please make your selection via actual swatches and colour boards available at our showroom.

Product Disclaimer: Ensure you read all product, technical and safety data sheets prior to application as liability falls on the applicator. All products must be applied in accordance with manufacturer’s recommended method.

Ray Nadar –

great coverage and it was easy to apply!