Australia Wide Shipping

Australia Wide Shipping

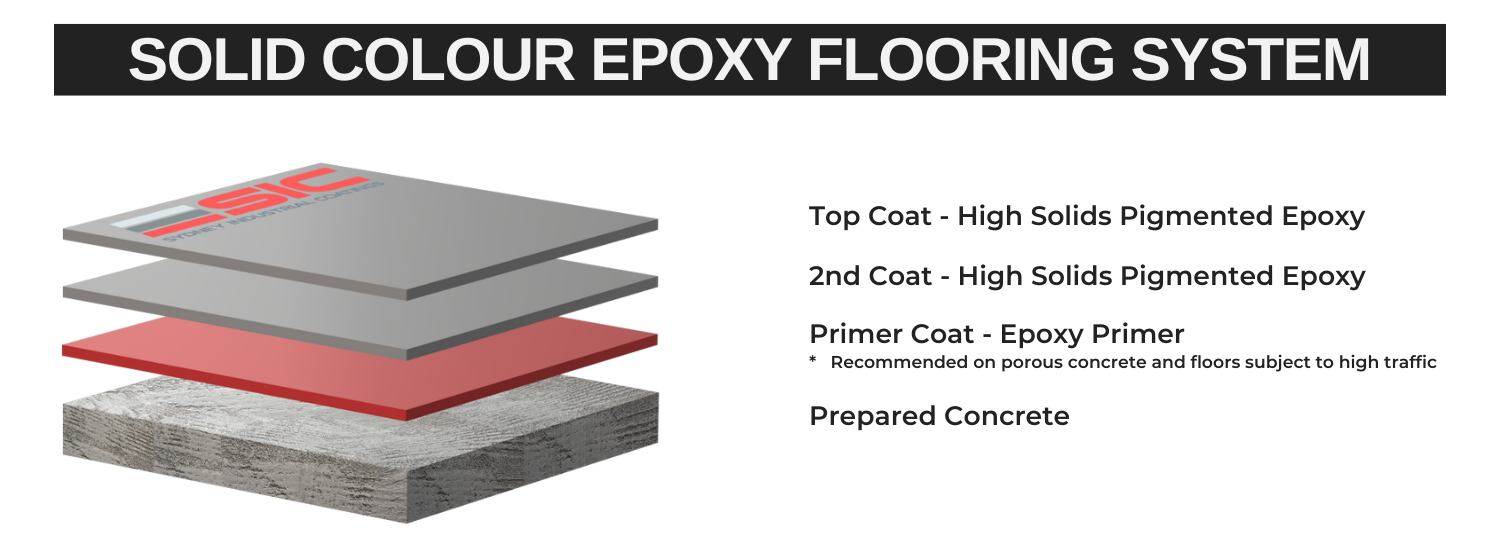

Solid color epoxy flooring is a popular choice for warehouses because it offers a range of benefits that make it practical, durable, and visually appealing. With its seamless and glossy finish, it adds a professional touch to the space, while its range of colors allows warehouses to customize the look to fit their brand or preferences. Epoxy flooring is also highly durable and resistant to heavy forklift traffic, chemical spills, and abrasions, making it an excellent choice for facilities that experience a lot of wear and tear. Additionally, the easy-to-clean surface of epoxy flooring means that maintenance is minimal, saving time and money in the long run.

Durability Epoxy flooring is extremely durable and can withstand heavy traffic, impacts, and abrasions. This makes it an ideal choice for warehouses, where there is constant movement of heavy machinery, equipment, and materials.

Chemical resistance Epoxy flooring is highly resistant to chemicals, including oils, solvents, and acids. This makes it an ideal choice for warehouses that deal with chemicals or have spills and leaks.

Easy to clean Epoxy flooring is easy to clean and maintain. A simple mop or sweep is usually enough to keep it clean.

Aesthetics Solid color epoxy floorings can enhance the look of a warehouse, is available in a variety of colors, and the smooth, glossy finish can brighten up any space to make it look more professional.

Safety Epoxy flooring can have slip-resistant additives incorporated to improve safety in the warehouse and comply with Australian Safety Regulations. This is especially important in areas where spills or moisture are common.

When considering solid color epoxy for your warehouse floor, it is important to talk with a professional installer who has experience with epoxy coatings. They can help you choose the right color and finish, as well as ensure that you have the knowledge to properly install an epoxy floor coating for maximum durability and longevity.

Showing all 6 results

To achieve a successful floor coating system make sure your surface is free of dust, oil/grease, any loose particles or paint and moisture. Click on the options below for further information

Epoxy Flooring Tools Information

Epoxy Floor Coating Preparation

Floor Grinders: Rubicon 480mm Grinder | Husqvarna 450mm Grinder | Scintex 250mm Grinder

Vacuums & Dust Extractors: Floorex | Husqvarna S36 (3 motor phase) | Husvarna S13 (single phase)

Diamond Grinding Plugs: Rectangle | Arrow | PCD (to remove previously coated or adhesives on the floor)

Redi-Lock Diamond Plugs: Sydney Industrial Coatings (9 pack)

Diamond Grinding Cup Wheels: 125mm to 250mm

Fill in all your cracks using a 2-pack epoxy filler and wait until the patching mortar is fully cured before grinding or coating the floor, this process usually takes a minimum of 6 – 8 hours.

For larger cracks and spalls: SIC Epoxy Coving & Repair Kit | Sika Sikadur 31 CFN

For smaller patching and cracks: Sika Sikadur 33 | Sikadur 513 (magic powder mixed into epoxy to thicken up)

General curing time (at 20°C) is a minimum of 8 hours. This can vary further if solvent has been added to the epoxy.

Sika Australia: Sikafloor 160 (up to 40sqm) | Sikafloor 94 (recommended) | Sikafloor 158W (moisture barrier)

UltraKote: High Solids Epoxy

Elite Crete Systems: E100-VB5 Epoxy Vapor Barrier

EpiMax: Epimax 237WB (water based)

This is an important step for if the coating is left uneven, this will show though your final coat. If this step if not completed within 30 – 36 hours (depending on temperature) of applying the previous coat, the floor will need to be scratched using an 80 grit sand paper.

General curing time (at 20°C) is minimum 8 hours.

High Solids Epoxies: UltraKote High Solids Epoxy

100% Solids Epoxies: Sikafloor 264 | Elite Crete Systems PT4 (pretinted)

UV Stable Polyurethanes: Sikafloor 359 AU | EpiMax 920

UV Stable Polyaspartic: EpiMax 842

Using thinners in the final (or finish) coat is not recommended. It is always recommended to back roll the product against the natural light to assist with achieving a more uniform finish. Wearing spike shoes to walk over the epoxy can help ensure the product is applied evenly, however you must apply safety practices and be cautious of injury.

Antislip media can be added to the topcoat to achieve a higher slip rating

Your floor will be trafficable after 24-48 hours and heavy items such as cars, boats or trailers shouldn’t be parked on the floor for 7 days after application of the final coat