Australia Wide Shipping

Australia Wide Shipping

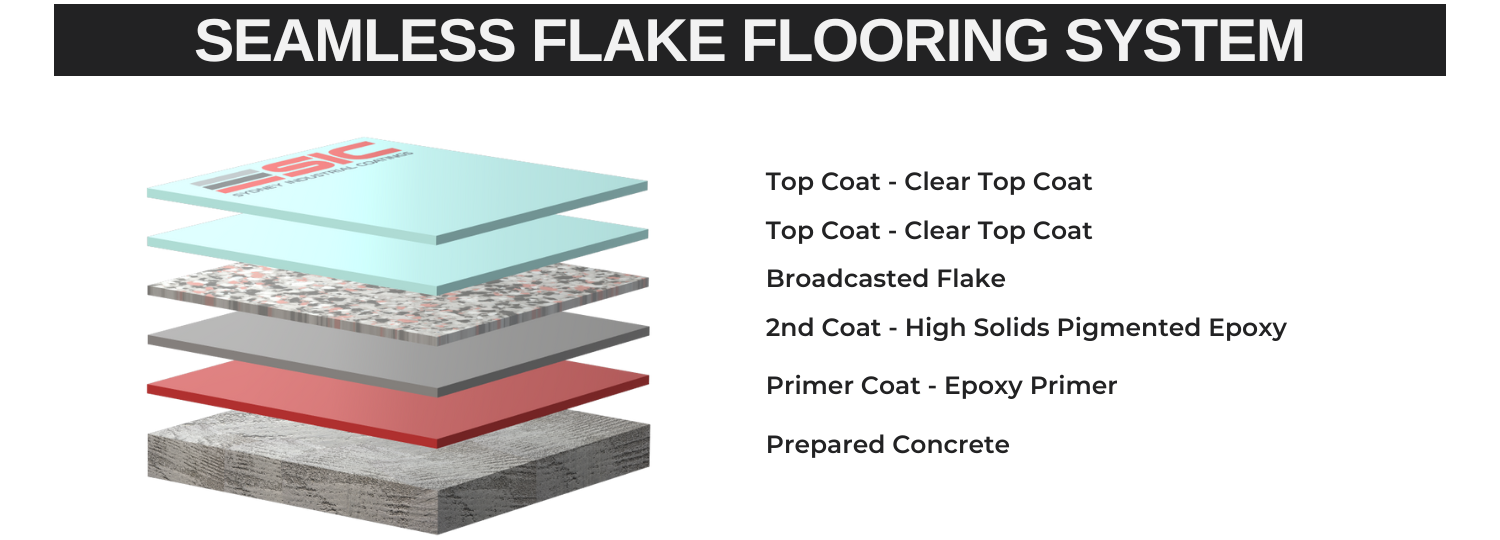

Epoxy Flake Systems are the most recommended flooring for showrooms and retail spaces as proven through the vast advantages that accompany this floor coating application. This method of epoxy flooring is made by broadcasting small chips or flakes of colored vinyl or acrylic onto a base coat of epoxy. The flakes are then sealed with a clear topcoat of epoxy to create a durable and attractive surface.

Flake epoxy flooring is a great option for retail spaces as it provides a unique and textured look that can hide imperfections, scratches and stains. The flakes come in a variety of colors and sizes, allowing you to create a custom look that complements your brand and product offerings.

Flake epoxy floors are also naturally slip-resistant, making it a safe option for high-traffic areas. It’s easy to clean and maintain, and the surface can be customized with logos or graphics to create a branded look personalised to you. Additional anti-slip media can be added if a higher slip rating is required.

When choosing a flake epoxy coating, consider the size and color of the flakes, as well as the overall aesthetic of your brand. It’s best to speak with a professional flooring contractor who can help you choose the right combination of colors and flakes to achieve the look you want for your showroom or retail space. Contact us today and speak with one of our highly qualified representatives.

Showing all 8 results

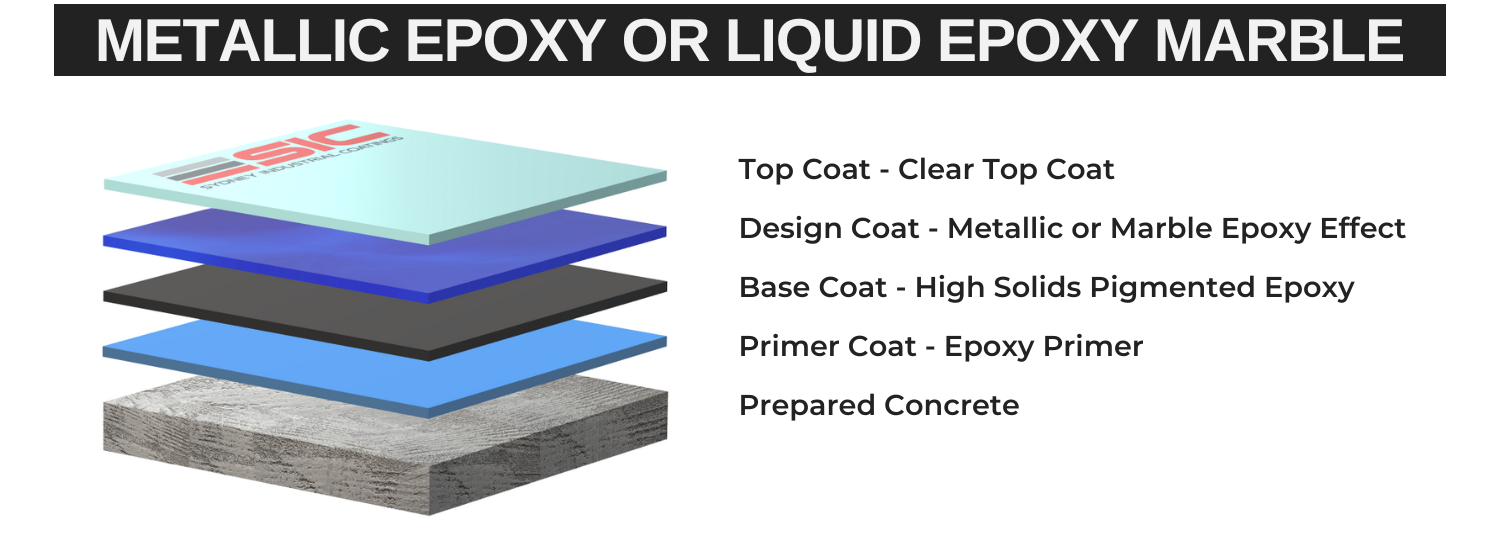

Metallic epoxy flooring and liquid epoxy marble flooring are both unique and visually stunning options for showroom and retail spaces.

Metallic epoxy flooring is created by mixing metallic pigments into clear, 100% solids, self levelling epoxy, which creates a shimmering, metallic effect on the surface. Metallic Epoxy Floors can be customized to create a variety of effects, including a liquid metal or pearlescent finishes, 3D effect flooring and even have multiple colours added in to create a floor unlike any other. This type of flooring is durable, beautiful, and easy to clean and maintain, making it an incredible option for showroom and retail spaces.

Liquid Epoxy Marble Effect finish is a type of decorative finish that combines the look of natural marble with the durability of epoxy floors. It is created by mixing a blend of pigments, fillers, and epoxy resin. This mixture is then applied over a surface and shaped, with the final effect being that of a natural marble looking surface. The mixture can be manipulated to create a variety of patterns and colors, allowing you to customize the look of your flooring and the final finish depends on the artist’s taste, skill level and quality of products used. Liquid Epoxy Marble Flooring is a very durable surface as it is chemical resistant, easy to clean, and can be used in commercial and residential areas; such as garages, theatre rooms, kitchens (including countertops) and other preferred areas as well.

Easy to clean

Metallic epoxy flooring is easy to clean and maintain, which makes it a great option for high-traffic areas, and will not harbour bacteria.

Reflective & Aesthetically pleasing

Metallic pigments that are used in creating the epoxy flooring finish gives it a glossy, reflective surface that can make a room appear brighter and larger. The metallic pigments create a unique and visually striking finish that can add depth and dimension to a room, making it a popular choice for decorating living spaces and commercial spaces.

Variety of colours

It can be customized to match any colour scheme, making it versatile and can be used to create different designs and patterns.

Both metallic epoxy flooring and liquid epoxy marble flooring provide a unique and visually stunning look that can enhance the appearance of your products and brand. However, these types of flooring are typically more expensive than other options and may require more maintenance to keep them looking their best. When considering metallic epoxy or liquid epoxy marble flooring for your showroom or retail space, it’s important to speak with professional flooring contractors who have experience with these types of materials. We can help you choose the right colors and finishes to achieve the look you want and ensure that the surface is properly prepared and installed for optimal performance and durability. If you would like to find out more, contact us today!

To achieve a successful floor coating system make sure your surface is free of dust, oil/grease, any loose particles or paint and moisture. Click on the options below for further information

Epoxy Flooring Tools Information

Epoxy Floor Coating Preparation

Floor Grinders: Rubicon 480mm Grinder | Husqvarna 450mm Grinder | Scintex 250mm Grinder

Vacuums & Dust Extractors: Floorex | Husqvarna S36 (3 motor phase) | Husvarna S13 (single phase)

Diamond Grinding Plugs: Rectangle | Arrow | PCD (to remove previously coated or adhesives on the floor)

Redi-Lock Diamond Plugs: Sydney Industrial Coatings (9 pack)

Diamond Grinding Cup Wheels: 125mm to 250mm

Fill in all your cracks using a 2-pack epoxy filler and wait until the patching mortar is fully cured before grinding or coating the floor, this process usually takes a minimum of 6 – 8 hours.

For larger cracks and spalls: SIC Epoxy Coving & Repair Kit | Sika Sikadur 31 CFN

For smaller patching and cracks: Sika Sikadur 33 | Sikadur 513 (magic powder mixed into epoxy to thicken up)

General curing time (at 20°C) is a minimum of 8 hours. This can vary further if solvent has been added to the epoxy.

Sika Australia: Sikafloor 160 (up to 40sqm) | Sikafloor 94 (recommended) | Sikafloor 158W (moisture barrier)

UltraKote: High Solids Epoxy

Elite Crete Systems: E100-VB5 Epoxy Vapor Barrier

EpiMax: Epimax 237WB (water based)

This is an important step for if the coating is left uneven, this will show though your final coat. If this step if not completed within 30 – 36 hours (depending on temperature) of applying the previous coat, the floor will need to be scratched using an 80 grit sand paper.

We recommend always having a minimum of two people when completing an epoxy floor, this is to ensure the product does not begin to cure before you have finished. If there is no one to help, we would suggest applying in sections based on works time and pot life of product being used.

High Solids Epoxies: UltraKote High Solids Epoxy

100% Solids Epoxies: Sikafloor 264 | Elite Crete Systems PT4 (pretinted)

This coat is ONLY to be completed with a product that is crystal clear, self levelling 100% solids epoxy. We recommend having one person mix and prepare the product whilst the other, let us call them the artist, applies and creates the design. As this coat is completed with a high body epoxy resin, a key note to remember is that the resin and design will look different as the curing process is occurring, applying a “less is more” technique can be beneficial. Wearing spike shoes to walk over the epoxy is essential with marble epoxy flooring, however you must apply safety practices and be cautious of injury.

100% solids, self level epoxy: Elite Crete Systems VR1 Crystal Clear Epoxy

Metallic Epoxy Pigments: Sydney Industrial Coatings Metallic Pigments | Elite Crete Systems Reflector Enhancer

Into Part A of the clear epoxy you will add the metallic pigment of choice and power mix until the powder has dissolved completely – You can mix your metallic pigment in the part a the night before to help with the saturation and mix of the powder. Once the pigment have dissolved, add your Part B, power mix for 2 minutes and apply to the floor to swirl or squeegee for the effect desired.

Liquid Epoxy Marble Solid Colour Pigments: UltraKote Pigments | Elite Crete Systems Pigments | Sikafloor Pigments

Into Part A mix a solid colour pigment as you would for your base coat. Make sure you do the same for the second batch which will be the secondary colour of your choosing. The size of the second batch will depend on preference and part B should only be mixed when ready to apply straight to the floor.

DO NOT use thinners in the final coat. It is always recommended to back roll the product against the natural light to assist with achieving a more uniform finish. If the floor is subject to heavy solvent, fuel or chemical spillage consider applying a two-pack clear top coat instead of a single pack.

Polyurthanes: UltraKote UVSeal | UltraKote SuperClear WB

Epoxy Glitter can be mixed into the final coat to create a stunning, eye-catching effect on the floor.

Your floor will be trafficable after 24-48 hours and heavy items such as cars, boats or trailers shouldn’t be parked on the floor for 7 days after application of the final coat